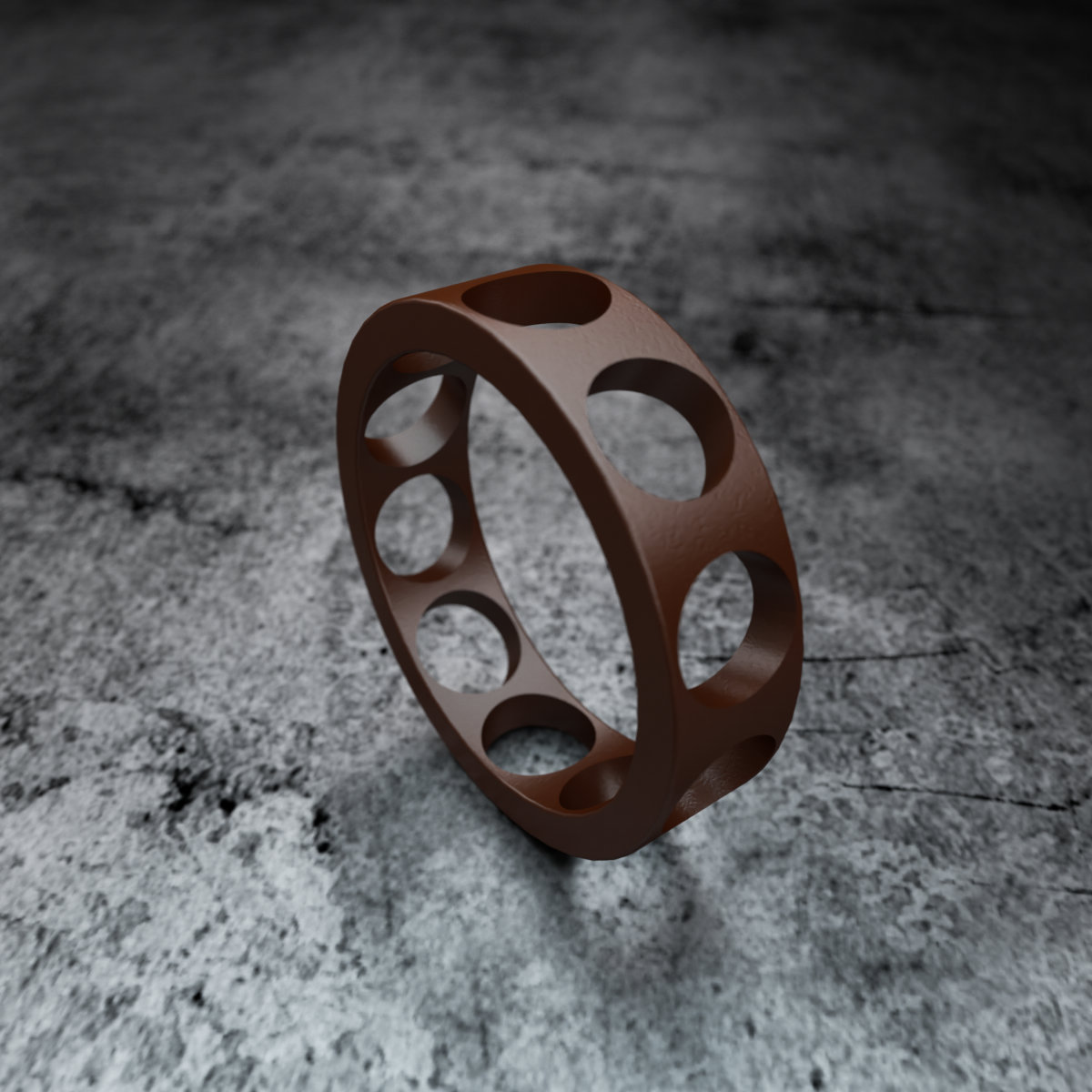

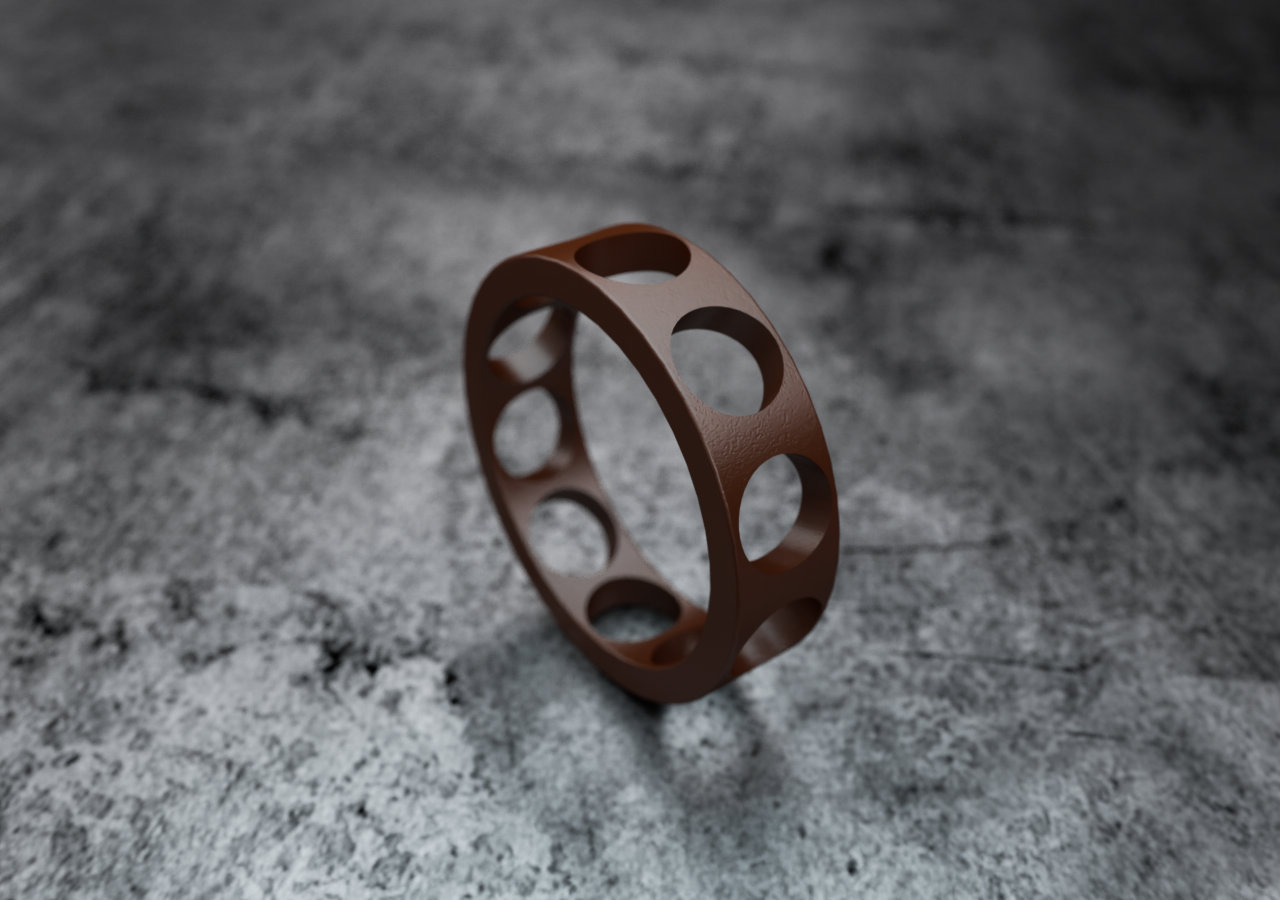

MATERIALS

RING AND ROLLING ELEMENT MATERIALS

| 100Cr6/1.3505 is low alloyed chromium steel with high carbon content. Its high hardness and homogeneous microstructure make it the optimum material for highly loaded rolling bearing components. 100Cr6/1.3505 has excellent wear resistance and outstanding resistance to contact fatigue.

100Cr6/1.3505 is a classic rolling bearing steel. pivotPRÄZISION GmbH specifies only high-purity material grades. These grades open up a wide range of applications. 100Cr6/1.3505 is suitable for the production of rings and rolling elements for all types of rolling bearings: e.g. ball, roller, needle and special bearings. By selecting a suitable heat treatment process, the material can be optimally adapted to the respective application. |

|

| AISI 440/1.3505 belongs to the high-alloy martensitic stainless steels. The combination of high carbon and chromium content ensures high hardness paired with excellent corrosion resistance compared to other martensitic stainless steels. Due to its high wear resistance and thermal stability, it is virtually predestined for high-quality stainless steel rolling bearings.

AISI 440/1.3505 is suitable for the production of rings and rolling elements for rolling bearings of any kind: e.g. ball, roller, needle and special bearings. Classical areas of application are the food and pharmaceutical industries. General applications with corrosive media in the environment as well as bearings in outdoor areas, e.g. conveyor belts or conveyor rollers. Furthermore, the excellent thermal stability qualifies the AISI 440/1.3505 for applications with increased operating temperature. |

|

| 1.4108 is a pressure embroidered, highly corrosion resistant martensitic stainless steel. A unique melting process and a special forging and rolling technique result in an extremely high degree of purity with a fine microstructure. In combination with the introduction of nitrogen, a high degree of hardness is achieved with outstanding corrosion resistance compared to other martensitic stainless steels.

1.4108 is suitable for the manufacture of rings for almost every type of rolling bearing: e.g. radial, axial, angular contact and special bearings. The material meets the highest requirements for corrosion resistance as well as mechanical and thermal stress. Classical areas of application are the food and pharmaceutical industries as well as applications with highly corrosive media in the environment. By using 1.4108, the service life of bearings subjected to high mechanical stress can be significantly increased. |

|

CAGE MATERIALS

| C10/1.0301 is regarded as unalloyed quality steel and is classified under general structural steels.

As cold-rolled strip steel, 08F is ideally suited for punching, folding and general deep-drawing operations with medium deformation. Due to its wide range of applications, C10/1.0301 is used in the automotive, construction and chemical industries. It is also used in the household appliance industry and for decorative purposes. In the rolling bearing industry, C10/1.0301 is one of the standard materials for the production of sheet steel bearing cages or ball, roller or needle roller bearings. Besides, C10/1.0301 is suitable for the production of general stamped and deep-drawn parts such as bearing housings of flanged bearings. |

|

| X12CrMnNiN17-7-5 / 1.4372 is an austenitic chrome-manganese steel. Its high corrosion resistance combined with good processing properties open up a wide range of applications.

Due to its excellent suitability for various surface treatments (polishing, brushing or grinding), X12CrMnNiN17-7-5 / 1.4372 is ideal for decorative purposes. Classical areas of application are the food, pharmaceutical and chemical industries. General applications with medium to highly corrosive media in the environment and outdoor applications. X12CrMnNiN17-7-5 / 1.4372 is suitable for the manufacture of cover discs (Z-discs) as well as sheet steel bearing cages or ball, roller or needle roller holders. Furthermore, X12CrMnNiN17-7-5 / 1.4372 is suitable for the production of general stamped and deep-drawn parts such as bearing housings of flanged bearings. X12CrMnNiN17-7-5 / 1.4372 is suitable for the manufacture of cover discs (Z-discs) as well as sheet steel bearing cages or ball, roller or needle roller holders. Furthermore, X12CrMnNiN17-7-5 / 1.4372 is suitable for the production of general stamped and deep-drawn parts such as bearing housings of flanged bearings. |

|

| PA 6.6 is a semi-crystalline thermoplastic. The material has excellent chemical resistance as well as reasonable sliding and damping properties. Compared to other polyamides, it also has higher mechanical strength and dimensional stability due to lower moisture absorption.

Due to its excellent mechanical and thermal properties, PA6.6 is suitable for the production of rolling bearing cages or ball, roller or needle holders. The strength and dimensional stability of the material can be further increased if required by adding various fillers (glass fibres, glass beads). The material is also used in a wide range of industrial sectors such as mechanical engineering, transport and conveyor technology, packaging and paper machines, electrical engineering, the automotive and textile industries. |

|

| Its excellent chemical resistance and good sliding properties round off the profile of this material.

PEEK is used in the rolling bearing industry as a cage material for a deep groove, angular contact and special ball bearings, among other things. The material is predestined for applications in highly demanding environments with high thermal and mechanical loads. Besides, its high chemical resistance combined with approvals for medical technology and the food industry makes it a very good alternative to conventional plastics. The material is used in many other target industries such as chemical, aerospace, automotive and vacuum technology. |

|

MATERIALS SEALS

| NNBR is a so-called synthetic rubber. It belongs to the plastic subgroup of elastomers. Due to its excellent chemical and physical properties, this material can be found in a wide range of applications.

Due to its excellent resistance, combined with good sliding and abrasion properties, it is an excellent material for sealing technology. NBR is the standard material for seals in the rolling bearing industry due to its excellent resistance to mineral oil and grease as well as its wide temperature range. The material is also used in various industrial sectors such as the automotive, packaging, pneumatic and hydraulic industries. |

|

| FKM is a mixed polymer of highly fluorinated hydrocarbon. It is assigned to the plastics group of elastomers.

The material was developed with a view to the constantly increasing demands on sealing technology. FKM is used as a sealing material in the rolling bearing industry. Due to its outstanding thermal and chemical resistance, as well as its resistance to ageing and ozone, this material has exceptional wear properties even under the most demanding environmental conditions. The material is also used in various industrial sectors such as the automotive and commercial vehicle industry, oil production, aerospace and chemical industry. |

|

| The ACM is an elastomer made of polar acrylic acids. The material is characterised by excellent chemical and thermal resistance.

Due to its polar structure, the material also shows excellent resistance to highly additive lubricants, which makes it predestined for use in sealing technology. ACM is used as a sealing material in the rolling bearing industry. Due to its excellent thermal and chemical resistance, as well as its resistance to ageing and ozone, this material has unique wear properties in challenging environmental conditions. Another significant application area is the automotive industry. There the material is used in valve covers, oil pan gaskets and transmission hoses. |

|

| The SPCC is a cold-rolled low carbon steel strip. It is considered unalloyed quality steel and is classified as general structural steel.

SPCC is ideally suited for punching, bending and general deep-drawing operations with medium deformation. Due to its wide range of applications, SPCC is used in the automotive, construction and chemical industries. It is also used in the household appliance industry and for decorative purposes. In the rolling bearing industry, SPCC is the standard material for the production of cover plates (Z-discs). Besides, SPCC is suitable for the production of general stamped and deep-drawn parts such as bearing housings of flanged bearings. |

|